Applications

A great solution for any reinforced concrete application!

Transportation

Bridges, restraint systems, and bridge decks

As a pioneer in the field of non-metallic reinforcement solutions for concrete structures and a leader in the construction of civil engineering works in North America, Pultrall has been building concrete bridges reinforced with V-ROD composite rebars for both repairs and new constructions.

Exposed to the effects of de-icing salts, these structures’ reinforcement is usually their greatest weakness. This results in expensive repairs and replacements of these structures that are far from reaching their expected service life.

With Pultrall’s V-ROD product…

User safety and infrastructure durability are the two key factors that make V-ROD the logical choice for designers, owners, and public–private partnerships.

For more information, consult the technical data sheets

Tunnels

Diaphragm walls

There are many construction techniques when it comes to tunnels, such as the cut-and-cover (open-pit) method or the more traditional bored-tunnel method. Of these techniques, the one that uses shields and tunnel boring machines (TBMs) is widespread and supposes the construction of a reinforced concrete launch box and extraction shaft.

Although well adapted to bore through concrete, TBMs are not well suited to work their way through a steel-reinforced concrete structure because of the resilience of the steel. The presence of this kind of reinforcement will seriously hinder the work of rotary cutters because of its ductility, absorbing the cutter’s energy and deforming instead of allowing them to fracture the concrete as they’re supposed to.

With Pultrall’s V-ROD product…

To work around these obstacles, V-ROD composite rebars are used locally in the area where TBMs go through the reinforced concrete wall. This section is called the diaphragm walls (Soft Eye). The elastic-to-rupture behaviour of V-ROD allows TBMs to bore through the reinforced concrete structure without presenting any more resistance than what would be experienced when boring through rock or unreinforced concrete.

The ultimate result is a reinforcement pattern that exhibits minor differences when compared to the steel version and a greatly improved work schedule, as the demolition step with steel reinforcement is no longer required. In brief, using V-ROD will translate to important savings.

For more information, consult the technical data sheets

Building structures

Multistory parking garages, balconies, foundations, and slabs-on-grade

The use of reinforced concrete in construction is a universally accepted and generally effective practice. However, there are a few applications for which steel is simply not enough.

These include structures like multistory parking garages, where the main, if not the only, cause of deterioration is corrosion of the reinforcing steel. Whether caused by the accumulation of chloride-based road salts or the location of open structures in coastal areas exposed to sea spray, corrosion of the reinforcing steel in these structures can have catastrophic and devastating consequences, ranging from property loss to human death, as shown by recent events.

With Pultrall’s V-ROD product…

In response to the growing issue of deteriorating parking structures, several solutions have been proposed but have limited effect, unless combined, which will significantly increase construction or repair costs. Therefore, the only effective solution is to use a reinforcement bar that simply does not corrode, and V-ROD, Pultrall’s composite rebar, offers you this unique advantage at a more competitive price.

Another application where V-ROD offers a significant advantage is in the balconies of apartment buildings. Its insulating properties will eliminate the need for thermal breaks to prevent heat and cold from affecting the indoor temperature, thereby reducing heating and cooling costs. In addition, when used in combination with steel reinforcement products in the floor slab of the building, it will ensure the continuity of the overall thermal protection envelope. Simplicity in design and construction, competitive prices, and energy efficiency are just some of the many benefits of using V-ROD in your residential multi-unit projects.

In the construction industry, foundations and slabs-on-grade still generally require the use of reinforcement to control concrete cracking caused by curing, temperature changes, or simply corrosion of the reinforcing steel. The V-ROD composite rebar offers unmatched performance in terms of tensile strength and corrosion resistance, making it the ideal solution for these applications.

V-ROD is also resilient, which means that, unlike steel, the rebar will bend when walked on and driven over but will return to its original shape once the pressure is removed. This property also allows concrete mixers to be brought close to the concreting site, thus avoiding the need for long-reach concrete pump trucks on your sites.

For more information, consult the technical data sheets

Electromagnetic

MRI equipment rooms, automated toll booths, electrical substations

The use of stainless steel, the grounding of the rebars, and the distancing of the rebars from the equipment are all techniques and methods used to avoid problems related to the magnetic properties of conventional steel rebars.

As we know, steel is a source of interference when an application requires an electrical signal to be transmitted between two elements or when the element is located close to a large source of energy.

With Pultrall’s V-ROD product…

In health-care facilities where magnetic resonance imaging (MRI) equipment is installed, magnetic fields that are 2,000 to 20,000 times stronger than the earth’s magnetic field are generated. In these cases, the use of conventional reinforcing steel in concrete elements near the equipment is prohibited to avoid any interference.

Also, the presence of steel near energy sources—in the concrete bases for inductance equipment in electrical substations or underground electrical distribution vaults, for instance—will result in more or less significant energy losses. Moreover, these losses imply an overheating of the reinforcement which will speed up the corrosion process and ultimately deteriorate the concrete.

In the case of detection loops and automated toll road systems, it is slightly different. A bad grounding of the reinforcing steel will interfere with the electromagnetic link between the metal of the vehicles and the detection equipment, which will result in false positives or false negatives.

The V-ROD composite rebars, being electromagnetically neutral and conducive to radio frequencies and cell phone signals, are the perfect solution for all these applications. They are a great alternative to nonconductive stainless steel, they do not require excessive concrete covers, and they do not need to be grounded. With composite reinforcement, all these costly measures are no longer necessary.

For more information, consult the technical data sheets

Marine applications

Wharves, seawalls, and breakwaters

Deterioration of reinforced concrete structures in marine environments due to chloride ion migration, leading to corrosion of the reinforcing steel in these structures, is a serious and widespread problem around the world.

The standard solutions to control corrosion of reinforcing steel, such as using cathodic protection (sacrificial anode or impressed current), increasing the thickness of the concrete cover, or adding corrosion inhibitors to the concrete, are generally expensive to install and maintain for some structures. They can also be complex to implement, and their effectiveness remains questionable to this day.

With Pultrall’s V-ROD product…

Pultrall’s V-ROD composite concrete rebar is the ultimate alternative to all these techniques. Totally non-reactive to chloride ions, compatible with other materials (no galvanic corrosion), and requiring no addition of additives to the concrete or increase in cover, our rebar is without a doubt your best option.

Moreover, having two to three times more tensile strength than reinforcement steel, the V-ROD rebar allows, in some cases, reducing the amount of reinforcement required while providing very effective control over the cracking.

For more information, consult the technical data sheets

Water treatment

Drinking water and wastewater

Over time, and often due to the conditions in which they operate, many industries experience problems with the degradation of their reinforced concrete infrastructures. For example, drinking water and wastewater treatment plants are particularly vulnerable to this type of situation.

The use of halogens such as chlorine, fluorine, or iodine in the disinfection of drinking water, as well as ozonation, has a devastating effect on steel products, whether it is black, galvanized, epoxy coated or even stainless steel. Obviously, disinfection is necessary to ensure the quality of the water distributed to the residents of the neighboring communities; therefore, measures must be taken to protect the reinforced concrete basins against the attacks of these aggressors. Markedly increasing the thickness of the concrete cover and using membranes that are expensive to apply and maintain are some of the methods that are generally preferred, but there is an alternative.

With Pultrall’s V-ROD product…

V•ROD, a composite concrete rebar manufactured by Pultrall, is totally inert and insensitive to these chemical or gaseous compounds. The use of our technology will reduce the cost of constructing a drinking water treatment plant by reducing the amount of concrete required as well as eliminating the need for membrane protection of tanks.

Likewise, wastewater treatment plants have their share of problems. However, their situation differs in terms of the main source of corrosion of metallic elements. The latter is the result of the action of hydrogen sulfide (H2S) produced by bacterial silt, which extends its destructive effects to both submerged structures and those in the atmosphere around these facilities.

For more information, consult the technical data sheets

Industrial applications

Aluminum smelters

In a completely different area and dealing with a very different problem, aluminum smelters are subject to overheating of the reinforcement in the slabs of the potrooms, which, in turn, damages the concrete.

Indeed, the high voltages used in the alumina transformation process and the loops created by the reinforcement pattern in the slab cause, by induction, significant energy losses and ultimately make the reinforcement a heating element. This accumulation of heat, which can reach a few hundred degrees Celsius, leads to a significant expansion of the steel and causes the concrete to crack by weakening the link between the reinforcement and the concrete.

With Pultrall’s V-ROD product…

Because V•ROD is an electromagnetically neutral solution, it is not affected by the magnetic fields associated with these processes and thus prevents the need to use stainless steel or a grounding solution for conventional steel reinforcement. Ultimately, V•ROD will reduce costs and ensure the sustainability of structures without all the drawbacks of other solutions.

For more information, consult the technical data sheets

Civil ingeneering works

Retaining walls

Retaining walls are among the structures that are subject to exposure to salt spray, whether it be from passing vehicles on roads where de-icing salts are used or from their installation in coastal areas.

The durability of these structures is frequently questioned, and seeing them reinforced with the so-called corrosion-resistant reinforcement is not uncommon. Other techniques used to extend the life of these walls include the use of sacrificial anodes or cathodic protection as well as the use of corrosion-inhibiting additives in concrete mixtures or the application of a sealant on the wall sections themselves.

With Pultrall’s V-ROD product…

This is an ideal application for V•ROD technology, which will not be affected by chloride intrusion into the concrete matrix, thus ensuring a longevity of these structures far beyond that usually expected. The V-ROD composite rebar is also much lighter than steel, making installation work much easier, either in the factory for prefabricated products or on the job site. In short, durable structures at a more reasonable cost are now within your reach.

For more information, consult the technical data sheets

Architectural concrete

Architectural concretearchitectural/decorative concrete structures

In coastal areas and in urban areas near roads where de-icing salts are used, witnessing the degradation of architectural/decorative concrete structures is not uncommon. Whether it is the coloration of the surface of the decorative concrete elements or, in the extreme, the collapse of parts of the concrete surface as a result of the corrosion of the reinforcing steel, these situations are highly undesirable and subject to significant rehabilitation and repair costs.

With Pultrall’s V-ROD product…

The V•ROD composite rebar is resistant to corrosion, thus avoiding the situations described above and ensuring the durability of investments made in decorative structures.

Aware of the reality of the market for architectural/decorative concrete pieces, Pultrall has developed a product specially adapted to this application. Indeed, the bars are white, a perfect complement to the natural color of the concrete. They are also nearly twice as resistant in tension as steel, allowing installation under minimal concrete cover and unparalleled shrinkage/cracking control. In short, these products offer an unmatched quality–price ratio.

For more information, consult the technical data sheets

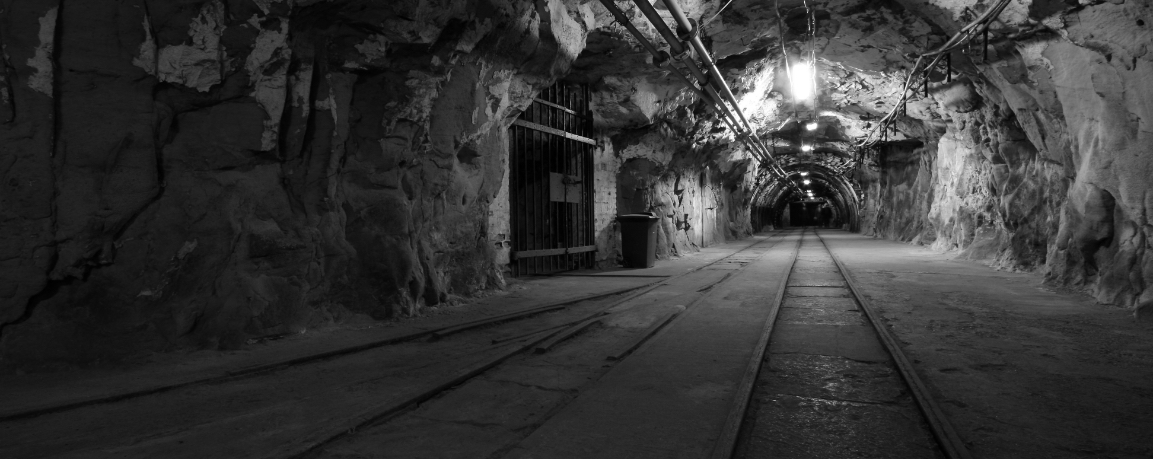

Mining

Anchorages and structures

Over the past decade, global mineral exploration budgets for non-ferrous metals have averaged over US$10 billion.

With all these new projects, and especially in cases of extraction of corrosive products, the need for a reinforcement solution for the concrete infrastructure of these mines as well as soil retention products is greatly accentuated.

With Pultrall’s V-ROD product…

Pultrall offers the mining industry and its stakeholders a solution to the deterioration of these structures by providing a composite concrete rebar that simply does not corrode. We also offer engineering and reengineering services for your mining project to adapt your steel requirements to V-ROD. We also have formwork rods and accessories as well as rock bolts.

Even though the corrosion of your equipment and structures represents a significant amount of money in rehabilitation and replacement, the health and safety of your workers must not be neglected, a vital element in the successful operation of a mine or exploration site. For all these reasons and more, Pultrall is the partner of choice for your mining projects.